Smarter Hoists.

Safer Operations

Reduced Downtime.

If you’re running an bridge crane, electric wire rope hoist, or gantry crane in a high-demand environment, real-time data can be the difference between seamless uptime and costly shutdowns.

That’s where HoistSense+ comes in.

Built for Industry 4.0, HoistSense+ transforms any electric hoist or crane into a smart, self-monitoring system that tracks wear, load, safety, and performance — 24/7.

What’s New? Wireless Load Sharing (Sub-1GHz)

The latest HoistSense+ upgrade introduces a powerful Sub-1GHz (433 MHz) wireless module that revolutionizes load sharing and multi-hoist coordination.

This new feature unlocks scenarios never possible before with the same safety and precision:

Multi-Hoist on a Single Crane

- 2 Hoists on 1 Crane: Precise balancing for long or irregular loads.

- 4 Hoists on 1 Crane: Even weight distribution across multiple hoists for complex lifting tasks.

Multi-Crane Coordinated Lifts

- 2 Cranes with 2 Hoists Each: Perfect for large tandem lifts or synchronized positioning.

- 4 Cranes with 1 Hoist Each: Enables expansive, coordinated moves across multiple cranes.

Improved Safety: Real-time wireless data minimizes risks of imbalanced loads.

Enhanced Efficiency: Faster setup and smoother tandem lifts.

Greater Flexibility: Handle unique scenarios that were previously challenging.

Future-Proof: Full backwards compatibility with existing HoistSense+ units.

Why Sub-1GHz?

- Superior signal penetration in industrial halls.

- Less interference than traditional Wi-Fi.

- Extended range for large-scale operations.

- No complex filtering — simple plug-and-play setup.

Why Choose HoistSense+?

- Prevent Breakdowns with early warnings for overloads, brake wear, and slack rope

- Optimize Maintenance with automatic service reminders and digital logs

- Increase Safety with overload protection and real-time load weighing

- Boost Efficiency using UltraSpeed mode when lifting lighter loads

- Enable Remote Monitoring with Wi-Fi or 4G cloud integration

- Comply with Regulations via built-in SWP (Safe Working Period) tracking

Whether you manage a bridge crane, wire rope hoist, chain hoist, or workstation crane — HoistSense+ is your digital supervisor on the job.

Key Features of HoistSense+ Smart Crane System

Real-Time Monitoring

- Tracks hoisting motor runtime, overloads, brake condition, and hoist wear

- Live load readings via strain gauge sensors

- Calculates remaining Safe Working Period (SWP) according to FEM standards

UltraSpeed Function

- Boosts hoist and cross-travel speeds when lifting under 25% of rated load

- Ideal for light-to-medium duty crane operations

Brake and Motor Protection

- Electro-magnetic brake wear sensors

- Integrated temperature monitoring in hoisting motor & control panel

- Prevents overheating and reduces unexpected failures

Monthly Reporting & Smart Alerts

- Get automated reports to email for usage, incidents, and maintenance reminders

- Optional alerts: Overload, overheat, inverter faults, short circuits & more

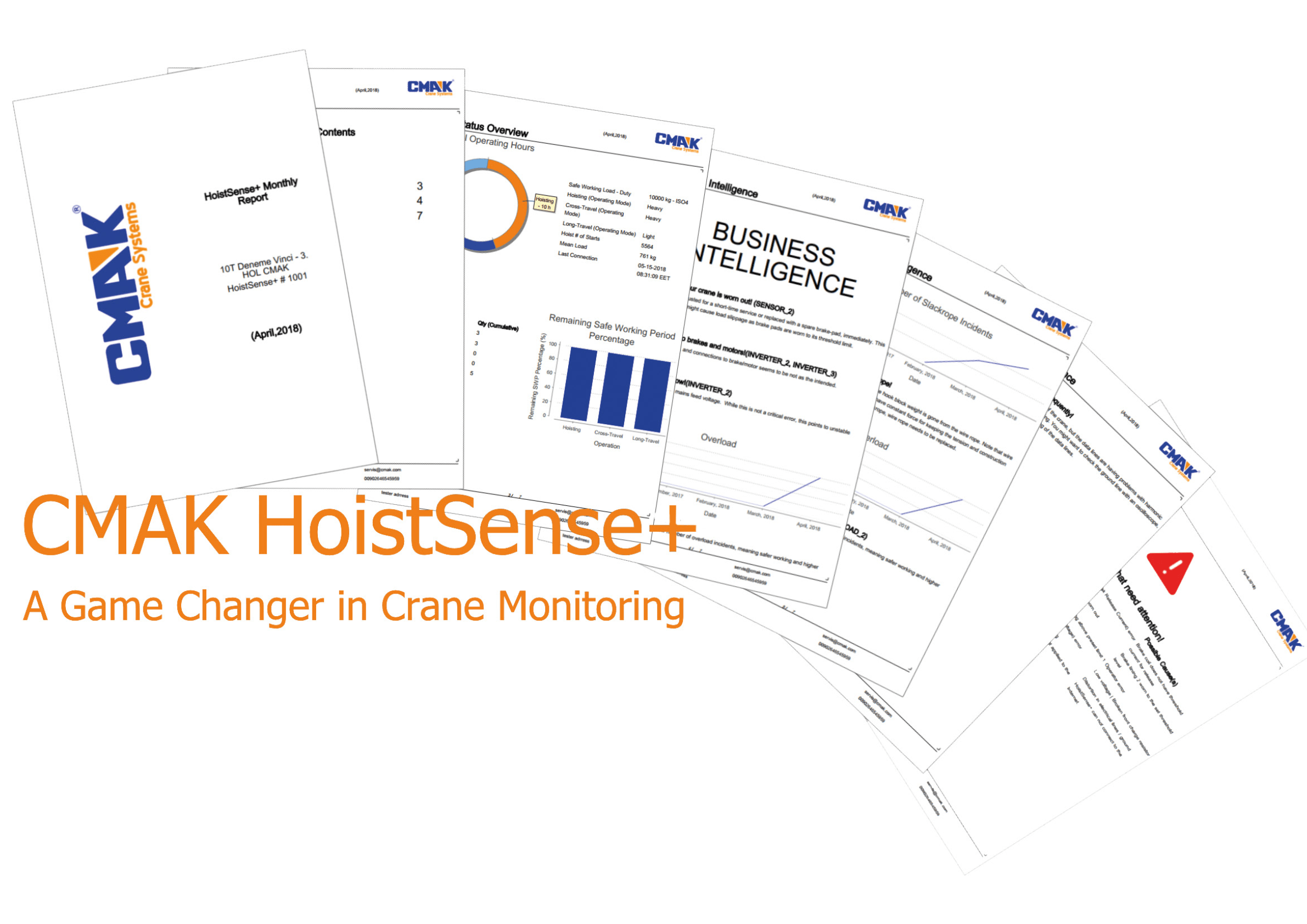

Sample Report Preview

HoistSense+ doesn’t just monitor — it documents. Each month, you’ll receive a comprehensive automated report directly in your inbox.

This report includes:

- Status Overview: Operating hours, Safe Working Period (SWP) remaining, and overall health.

- Business Intelligence: Actionable insights such as voltage issues, operator habits (e.g., excessive load swinging), or grounding problems.

- Alerts Log: Detailed list of overloads, overheating, slackrope incidents, and inverter faults.

Here’s an example of what the HoistSense+ Monthly Report looks like:

With these reports, your maintenance team has clear visibility into crane performance and can plan preventive actions before issues turn into downtime.

Load Sharing & Slack Rope Detection

- Connect up to 4 cranes or hoists for real-time load balancing

- Ensures safer multi-hoist lifting operations

- Alerts operators when slack rope conditions are detected

Intelligent Business Insights

Crane supervisors often rely on experience. With HoistSense+, you get decades of predictive knowledge baked into your equipment — allowing you to:

- Detect unsafe usage patterns

- Prevent costly downtime

- Extend equipment life

- Plan ahead with data-driven decisions

Compatible With All Hoist Types

HoistSense+ can be added to:

- Electric wire rope hoists

- Bridge cranes

- Monorail hoists

- Gantry and semi-gantry cranes

Whether you’re using a 5-ton bridge crane, a manual chain hoist, or a custom 20-ton gantry crane, HoistSense+ integrates smoothly with CMAK equipment or third-party systems.

Ready for Industry 4.0

The MK-III package supports full internet connectivity (WiFi / GSM / Ethernet), allowing:

- Live remote access from anywhere

- Automatic email alerts on crane alarms

- Seamless cloud-based record keeping

- Smart diagnostics using inverter data

HoistSense+ Models

Feature | MK-I | MK-II | MK-III |

Load Weighing | ✅ | ✅ | ✅ |

Real-Time Monitoring | ✅ | ✅ | ✅ |

UltraSpeed | Hoisting & Trolley Travel | All motions | All motions |

Brake Monitoring | ❌ | ✅ | ✅ |

Monthly Reports | ❌ | ❌ | ✅ |

Industry 4.0 Connectivity | ❌ | ❌ | ✅ |

Slack Rope Detection | ✅ | ✅ | ✅ |

Wireless Load Sharing (433 MHz) | Wired / Wireless up to 4 machines | Wired / Wireless up to 4 machines | Wired / Wireless up to 4 machines |

Ready to Make Your Crane Smarter?

Upgrade your electric hoist or bridge crane with HoistSense+ and step into the future of predictive crane maintenance and supervision.

Become a CMAK Dealer to offer Industry 4.0 hoist monitoring solutions to your clients.

Or Contact Us to request a demo or quote tailored to your crane fleet.

HoistSense+ – FAQ

What is HoistSense+?

How does HoistSense+ improve efficiency?

Can HoistSense+ be integrated into existing cranes?

No. HoistSense+ cannot be retrofitted to existing cranes or hoists. It is available only with new CMAK NXS hoists that are fully prepared for this technology at the factory. For customers requiring load monitoring on existing cranes, we can recommend alternative solutions such as load cells or other monitoring systems.

Does HoistSense+ support Industry 4.0 connectivity?

How does HoistSense+ help with maintenance?

How does the new wireless load sharing work?

The Sub-1GHz module allows safe, interference-free synchronization between multiple hoists and cranes for tandem lifts, balancing, and complex handling.